(Click on most pics for a larger version)

Last updated: Monday, September 2, 2007 .

|

(Click on most pics for a larger version) Last updated: Monday, September 2, 2007 . |

[Page 1] [Page2]

Intro:

This article is intended to collect together technical info and practical hands-on data about the venerable Dana 60 front axle. It is not a how-to article, but more a collection of information and facts. With an article of this scope, it is very difficult to personally verify all the information or ensure complete accuracy, but I have attempted to be as complete and accurate as possible. Keep in mind that nothing in the axle world is cast in stone, variations are always possible.

Disclaimer:I do not recommend nor endorse any of the modifications shown in this article, the information is provided for personal information purposes only. I am not an Engineer, metallurgist, or mechanic - I have absolutely no professional qualifications whatsoever in this regard - I have simply collected information from others. Use of any of the information contained herein is at your own risk. It is therefore your responsibility to maintain safety in and around your vehicle at all times. It is likely that some procedures featured here may void your vehicle's (or parts thereof) warranty. It is also likely that some of the information featured shows procedures that may not be legal for street use in some or all states within the US and/or any other countries and may not be safe for on or off-road use. The article's author, nor anyone related to this web page, cannot be held responsible for any damage, failure, or violations of the law, that might result from from the use of any information contained on this page, or linked to on this page .

In particular I do not recommend the grinding of brake callipers, nor the conversion of dual rear wheel (DRW) hubs to single rear wheel (SRW) hubs, as these components were never designed to be modified and used in this manner.

Acknowledgements:There is no way all this information could have been compiled without the help of a great number of people - some knowingly, most not. I harvested the information from about 1999-2002 mostly from the most excellent Pirate4x4.Com Bulletin Board, but also from other knowledgeable wheelers, manufacturer's web sites, and the personal experience of my club mates and I. If you notice any errors, please let me know via our club bulletin board The Right Coast Crawlers BB. If you notice pictures or large portions of text that are yours and you would like specific credit, let me know. Also, if I have used pictures of yours that you object to, please let me know so that I can remove them. With that said, I must give thanks to the following list of folks, although the list is by no means complete:

Sherpa rig, Patooyee, 66CJDean, Wolf 359, Onetonwillysands10, Scott at Rockstomper, Emsoffroad, Alpo, Ant, Aggro, BadDog, BigDude, PinBall, Ultim8kaos, Chad.

Extra special thanks to Steve Gerstner of Differential Engineering for taking the time to call me personally, all the way from Florida, to correct many of my mistakes and to share a little of his vast knowledge. Steve is one of, if not the, premier custom axle builder in North America. He has personally handled over 500 Dana60 front axles......now THAT's experience!!

Attachments:The following documents located on our server provide additional information and data on the Front Dana 60

Dana Spicer light Axle service manual.

Links:| CTM http://www.ctmracing.com/dana60.shtml Dutchman http://www.dutchmanms.com/ Dynatrac http://dynatrac.com/ Randy’s http://www.ring-pinion.com/ Moser http://www.moserengineering.com/ Superior http://www.superioraxle.com/ WMS http://www.wagonermachine.com/ Custom Differentials http://www.custom-differentials.com Boyce Equipment http://www.boyceequipment.com Shaker http://www.shakerbuilt.com Differential Engineering http://differentialeng.com/ Six States http://www.sixstates.com |

4wd Factory http://www.4wdfactory.com/ Parts Mike http://www.partsmikeparts.com/60Front.htm JB’s 4x4 http://www.jbs4x4.com./ Warn http://www.warn.com/ ORD http://www.offroaddesign.com/ Sunray http://www.sunrayengineering.com DTD http://www.drivetraindirect.com/ DTS http://www.drivetrainspecialists.com/ WCD http://www.differentials.com/ Reider racing http://www.reiderracing.com/ Rockstomper http://www.rockstomper.com/ Milemarker http://www.milemarker.com Superwinch http://www.superwinch.com |

ORCs 35 spline stub shaft upgrade article http://www.off-road.com/chevy/tech/dana35spline/

ColoradoK5 article on installing a Boyce Equipment rebuilt Dana 60 http://www.coloradok5.com/boyce.shtml

ColoradoK5 Dana 60 calliper grinding article http://www.coloradok5.com/d60calipergrind.shtml

Alaska Offroad axle tech page http://www.alaskaoffroad.com/axle_tech.htm

Off-road.com Dana 60 tech http://www.off-road.com/chevy/tech/dana60

Mike Knorr's Building an RC D60 http://www.bc4x4.com/tech/2001/hpd60front/

Wolf359's Dana 60 upgrade article http://www.gohumvee.com/images/Tech/60axleup/index.html

Description:The Dana 60 front axle is a heavy-duty 4wd front steering axle manufactured by Dana Spicer corporation. It was most commonly used in many one ton and some 3/4 ton pickup trucks.

Over the years there have been many different variations, from early Ford closed knuckle low pinion types, to the common GM kingpin low pinion, to the 94+ Dodge Dana 60 with a vacuum operated central axle disconnect, balljoints, and 32 spline inner shafts.

The most desirable axles for heavy duty 4x4 use in stock form have open kingpin knuckles, 35 spline inner axles, 30 spline outer axles (stub shafts), and disc brakes. Later model Ford high pinion (HP) Dana 60s with balljoints instead of kingpins are also desirable axles, though many prefer the kingpin knuckles over the balljoints.

The undesirable front Dana 60 axles will not be covered by this article, and include:

74-75.5 Ford low pinion drivers side closed knuckle drum brake with 30 spline inners, 19 spline outers, small ujoints and weak knuckles.

75.5-77 Ford low pinion drivers side open knuckle disc brake 30 spline inners, 19 spline outers, outer knuckle spindle pilot hole is smaller than 78+ axle and is therefore notched to allow 1480 series U-joint tp pass through.

94+ Dodge drivers side low pinion CAD unit bearing hub 32 spline 1.31” coil sprung Dana 60s

Any other closed knuckle Dana 60, like those from a Jeep M715 that had coarse spline axles.

Common applications for the desirable axles include:

GM

1977-87 K30 1 ton 4wd

1984-88 CUCV

1988-91.5 V30

All GM / Chevy versions were passenger side differential, regular rotation (low pinion) gears, disc brakes, 35 spline inners, 30 spline outers, internal style hubs, and kingpin knuckles.

Dodge

1975-89 D-600

1992-93 D-600

1981-89 D-700

1992-93 D-700

All these Dodge versions were passenger side differential, regular rotation (low pinion) gears, disc brakes, 35 spline inners, 30 spline outers, and kingpin knuckles. 1979-89 versions had external style hubs, with the earlier versions with full-time NP203 Transfer cases having external drive flanges, and later models having external lockout hubs. The external lockout hub bolt pattern is 8 x 3.960". The 90-93 versions had internal style hubs just like the Chevy and lockout hubs. One caution with dodge applications, is you have to be careful to avoid the Dana 61 front axle. 1987-88 and 1991-93.5 Dodge D600 and D700 also came with Dana 61. More info on the Dana 61 later in the article.

Ford

1978-79

F-350 and some F-250 (Snofighter and High GVW packages)

1986-88 F-350 with dual rear wheels (DRW)

1988-91.5 F-350 with single rear wheels (SRW)

1992-95 F-350 (all) (balljoint)

1996.5-98 F-350 (all) (balljoint)

2000 F350/F450/F550 DRW (balljoint, metric 8x170mm wheel bolt pattern F350 / 8x220mm F450/F550, unit bearing hub)

2000.5 F350/F450/F550 DRW (balljoint, metric 8x170mm wheel bolt pattern F350 / 8x220mm F450/F550, unit bearing hub)

2001 F350 DRW (balljoint, metric 8x170mm wheel bolt pattern, unit bearing hub)

2001-02 F450/F550 DRW (balljoint, metric 8x220mm wheel bolt pattern, unit bearing hub)

2002 F250/F350 SRW (balljoint, metric 8x170mm wheel bolt pattern, unit bearing hub)

2002 F450/F550 DRW (balljoint, metric 8x220mm wheel bolt pattern, unit bearing hub)

All these Ford versions were drivers side differential, reverse-cut (high pinion) gears, and kingpin knuckles to 1991.5 and balljoints thereafter. Most Ford D60s are internal style hubs, but external type lockout versions do exist. 2000 and later Ford D60s have balljoints, a metric wheel lug pattern of 8x170mm up to F350 and 8x220mm for F450/F550, different brakes and spindles, sealed "unit-bearing hubs", hub-centric wheels, different length axleshafts from the earlier D60s, and larger Superduty specific tie rod ends. From 2000 on, the Ford D60 front axle is also known as the Model 60F2000+ or the 248M. 248 just happens to be the equivalent in millimeters of 9.75" - the diameter of the D60s ring gear.

IHC

1975 1300 camper Special

35 spline inner, 30 spline outer, external lockouts

This paragraph is just a quick summary of the most notable differences, more detailed info is spread throughout the article in the dimensions table, parts interchange table, etc.

Dodge and Chevy front Dana 60s are very similar, and in many cases fairly interchangeable - both parts and entire assemblies. Differences do exist, and some are:

1) All Chevy D60s are kingpin knuckle, whereas early (79-93 ) Dodge are kingpin and later (94+ ) are balljoint (and undesirable)

2) All Chevy D60s are internal style lockout / drive flange bearing hubs, whereas early (79-89 ) Dodge are external, and later Dodge (90-93) are internal.

3) Dodge and Chevy outer kingpin knuckles are very similar, and either will bolt to the other axle, but they are not identical - tie-rod placement is different - the Dodge mounts the TRE about an inch and a half higher. Tie rod end taper is the same for all Chavy, Dodge up to 93, and 78-79 Ford. 85+ Ford is smaller to 99, then 2000+ Ford Superduty is larger and Super-duty sepcific.

4) Chevy leaf spring pads are 3 inches wide and 32 inches apart (center-pin to center-pin), Dodge are 2.5 inches wide and 32.5 inches apart.

5) All SRW Chevy D60s are 69" wide wheel-mounting-surface to wheel-mounting-surface (wms-wms). Most SRW Dodge are 67" wide, although some are reportedly 69" wide too. A Dodge DRW D60 is 75.5" wms-wms.

6) Chevy rotors are 1.5" thick, early dodge rotors are 1.25" thick, but the calipers are identical. Dodge D60s from the CTD years (90-ish to 93) have 1.5" rotors.

7) Dodge D60s from the CTD years (90-ish to 93) have a higher tierod location than the older Chevys.

Differences between the Chevy/Dodge D60 and Ford D60 are more numerous and apparent. They include

1) Chevy/Dodge use a 6 bolt spindle mount pattern, Ford is 5 bolt

2) The Chevy/Dodge spindle and bearing/wheel hub are 5/8" longer than the Ford.

3) The

Chevy/Dodge stub shaft is 0.600" longer than the Ford stub shaft

4) Chevy rotors are about 1.5" thick, the Ford and Dodge rotors are about

1.25" thick

5) Virtually all Ford front disc brakes used 2 piston calipers

6) The Chevy/Dodge outer knuckle is clearanced for their large single-piston calipers, the Ford are not.

7) The Chevy/Dodge caliper mounting bracket bolts on AFTER the spindle, as in knuckle-->spindle-->caliper bracket, whereas the Ford mounts the caliper bracket between the knuckle and spindle, as in knuckle-->caliper bracket-->spindle

8) The Chevy/Dodge are passenger drop regular cut low pinion diffs, the Ford are drivers drop reverse cut high pinion.

9) Chevy/Dodge uses six 1/2" spindle studs, Ford uses five 7/16" spindle studs

10) Ford knuckles seem to have more issues with the upper kingpin area strength than others. Chevy/Dodge knuckle has thicker ribbing around the upper kingpin area.

11) Ford knuckles have a shorter steering arm than the Chevy/Dodge. A 1.5" diameter tie-rod on a stock Ford D60 will justtouch the diff cover at full lock. The same tie-rod on a GM Dana 60 would be just over 1/2" away from the cover at full lock.

Axle identification by BOM:Here is a table of front D60 axles showing Bill of Material (BOM) numbers, sorted by manufacturer.

The same table is also available in Microsoft Excell spreadsheet format (.xls) so that you can save it to your computer and then easily, search, filter, and sort the data any way you like to get the information you need.

This table also lists all axle shaft lengths

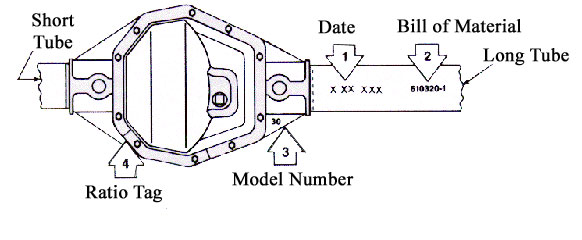

The BOM is stamped on the axle housing tube as indicated in the picture below. Unfortunately, they are not stamped very deeply, and in harsh winter climates are often illegible after many years. In some cases, the BOM is also stamped on the outer circumference of the ring gear.

Stock Dana 60 front axle dimensions

The wms, spring pad span, and spring pad width are subject to error and variations. Take with a grain of salt, and please send me corrections / info that you have, as well as info for filling in the blanks.

| OEM | Years | Application | knuckle | diff | gears | springs | width (wms-wms) | hubs | Splines

(inner / outer) |

approx spring pad span | Spring pad width | Calipers | Spindle bolts | pinion centerline to knuckle centerline |

| Chevy | 79-87 | K30 | kingpin | pass. | regular | leaf | 69.5" | internal | 35 / 30 | 32" | 3" | single piston | 6 | |

| 88-91 | K30 crew cab | kingpin | pass. | regular | leaf | 69.5" | internal | 35 / 30 | 32" | 3" | single piston | 6 | ||

| Dodge | 79-91 | D-600 & D-700 | kingpin | pass. | regular | leaf | 67.5" | external | 35 / 30 | 32.5" | 2.5" | single piston | 6 | |

| 92-93 | D-600 & D-700 | kingpin | pass. | regular | leaf | 67.5" | internal | 35 / 30 | 32.5" | 2.5" | single piston | 6 | ||

| 85-88 | DRW D-600 & D-700 | kingpin | pass. | regular | leaf | 75.5" | external | 35 / 30 | 32.5" | 2.5" | single piston | 6 | ||

| Ford | 78-79 | F250/F350 | kingpin | drivers | reverse | leaf | 69.25" | internal | 35 / 30 | 31.5" | dual piston | 5 | ||

| 85-91.5 | F350 | kingpin | drivers | reverse | leaf | 69.25" | internal | 35 / 30 | 36.5" | dual piston | 5 | about 3.5" more to drivers side than 78-79 | ||

| 92-99 | F350 | balljoint | drivers | reverse | leaf | 69.25" | internal | 35 / 30 | 36.5" | dual piston | 5 | about 3.5" more to drivers side than 78-79 | ||

Identification:

The following pics are of a 1980 Chevy K30 D60

Miscellaneous Front D60 pics:

Specs:

Max

load (SRW): 4500lbs,

Max torque short duration: 5550 Lbs.Ft. Continuous: 1500 Lbs.Ft. - these figures

unconfirmed

Axle tube dia. 3.125", wall thickness 0.5"

Weight center section = 120lbs.

Weight, fully dressed single wheel front Chevy 60 complete, locking hub to hub 518lbs

Weight, fully dressed single wheel front Ford RC 60 complete, locking hub to hub 460-480lbs

Max steer angle = 40 degrees

Cover Bolts: 10

Diff cover 10-3/4 X 11-1/2"

Side

gear spline24/48 pitch,30T 1.250 P.D.

Ring Gear dia.=9.750", tooth width 1.4370"

Ring Gear Diameter: 9 3/4"

Ring Gear Bolts: (12) RH Thread 1/2" X 20

Pinion Shaft Diameter: 1.625"

Pinion

Splines: 1.2760" 29 Involute Splines

Carrier split, regular cut: 4.10 down / 4.56 up

Carrier split, reverse cut: All use same carrier **

** Note: The carrier is the same for all Ford RC 60's UP TO 98, and is the same

as the GM/Dodge 4.10 carrier - namely part # 706040X.

BUT - the Ford RC60 was never offered stock with a ratio lower than 4.10

in those years. When aftermarket vendors started making gears lower than 4.10

for RC 60s - they made the ring gear thick, so it could just go on the stock

carrier. So if you bought aftermarket 5.38 gears for RC60 - they would likely

be thick. Now - if you buy an aftermarket carrier (i.e. locker, spool,

limited slip) for your RC60 - I imagine, depending on where you buy it from,

they ask "year/make/model" and based on that would likely sell you

the 4.10 down Detroit - that way - if you already had aftermarket lower gears,

they would just go on the locker. The problem you might run into, is this:.

You buy aftermarket gears first - lower than 4.10 and they're thick. Then you

buy a locker by ratio, not make and model, and naturally you'd think "I

have 5.13 gears - I must need the 4.56 and up locker" but you get hooped

because the gears are thick, and won't go on that carrier. Also note, The 2000+

RC60 Fords are offered with stock gears as low as 5.38 - but these are not thick

to go on the same old 4.10 down carrier - they are thin and go on the same GM/Dodge

4.56 up carrier. The carrier break is 4.30 and down go on the 4.10 and down

carrier. I don't know if Spicer is the only manufacturer offering thin

RC60 gears - but the bottom line is - when dealing with an RC60, you do have

to match your carrier and gear set.

To distinguish a 4.10 and down carrier (called a 3-series carrier) from a 4.56 and up carrier (called a 4-series carrier) you need to measure the distance from the face where the ring gear sits, to the end of the carrier, as shown in the following pic - labelled dimension "A".

For a 3 series carrier (4.10 and down, Spicer part number 706040X) Dimension A is 2.225"

For a 4 series carrier (4.56 and up Spicer part number 706041X) Dimension A is 2.360"

Carrier construction: malleable iron (fine grain cast iron)

Ring and Pinion construction: 8620 heat treated

Differential housing construction: Nodular iron

Axle tubes construction: mild steel

Inner knuckles (aka tube forks, end forgings, or "Cs") - forged, premium low-carbon mild steel

Outer knuckle construction: malleable iron

Axle tube to diff interference fit: .006" - .010"

Axle tube to inner yoke (C) interference fit .003" - .005"

Distance between axle tube centerline and bottom of diff: 6.0"

D60 pinion nut size - 1 5/16

Diameter of kingpin cap - 2.25"

Differential fluid capacity - 6 pints (3.4 liters) 80w90 hypoid gear lube

Wheel hub hole for 1/2" wheel studs(Ford '76-'79) - 0.580"

Wheel hub hole for 9/16" wheel studs (ford 85-97) - 0.600"

Front Dana 60 parts interchange:The following parts interchange between Chevy, Ford, and Dodge front kingpin Dana 60s as indicated in the table below in the “interchange between” column, where C indicates Chevy, F indicates Ford, and D for Dodge.

The “Description” column is the name of the part as it is commonly known, and the column “Dana’s Description” is the description of the part according to Dana’s web site.

This info can be extremely useful when figuring out what parts can and cannot be used on an axle or custom project. Note, the absence of a part on this list DOES NOT mean it is not the same / does not interchange – it simply means that there was not a Dana part number listed for that part for all 3 manufacturers on Dana’s web site. This is usually because either a manufacturer uses their own part, own part number, or the information is no longer available. For example, the diff cover gasket for a Chevy and Dodge Dana 60 is part number 34687, but for a Ford it is listed as “Ford 60F variable parts table” when you look it up on Dana’s web site, but I’m fairly certain all 3 are the same. The same goes for parts like the diff cover fill plug and king pin cap grease fitting, which I’m pretty sure will all interchange but I can’t swear to it. In the same vein, you can use information in the chart to infer facts, even though they are not presented as such. For example, Dana does not list the same part number for Chevy and Dodge diff covers. However, using the chart we can see that the diff cover gaskets and even the cover bolts interchange, so from that, and knowing they are both standard cut low pinion Dana 60s, we can pretty safely infer that the covers do interchange.

Other sections of this article lists parts that are commonly know to interchange between axles.

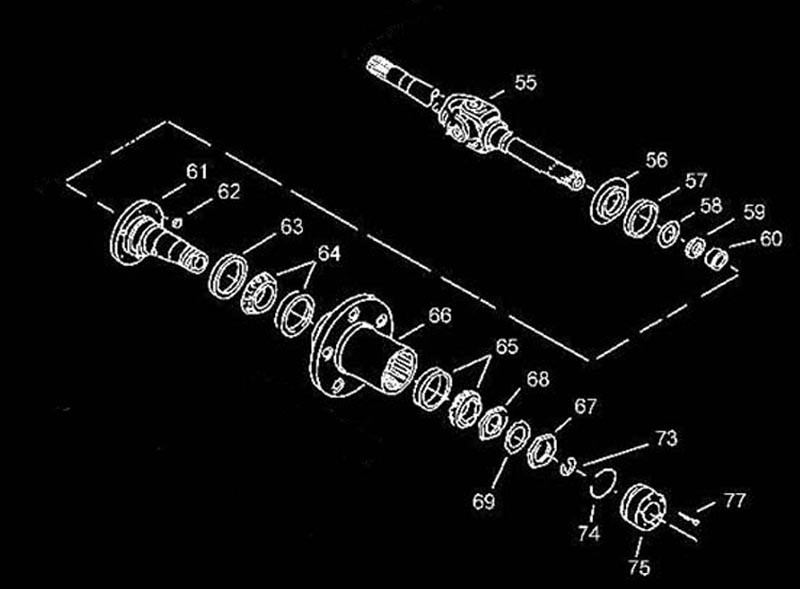

Refer to the diagram below for picture / location of the part. Note, the pic is of a Dodge Dana 60. Click for large view. For an exploded view of the Chevy Dana60 click HERE. For an exploded view of a Ford Dana60 click HERE: (note, for these 2, the diagram numbers in the pics do not correlate with the table below).

Huge thanks so Steven J Meyer for providing much of the raw data on his website.

| Diagram # | Dana / Spicer part number | Description | Interchange between | Dana’s Description |

| 003 |

34643 |

Front pinion oil slinger |

CDF |

SLINGER - PINION BEARING INNER |

| 004 |

70604x |

Front pinion bearing and race |

CDF |

INNER PINION BEARING KIT |

| 005 |

706359x |

Pinion shims |

CDF |

KIT - PINION BRG ADJ SHIM |

| 006 |

708020 |

D only C & F # 706375X |

KIT - DIFF & PINION ADJ SHIM |

|

| 30982 |

C & F |

BAFFLE – PINION BEARING |

||

| 007 |

706045x |

Rear pinion bearing and race |

CDF |

OUTER PINION BEARING KIT |

| 008 |

42737 |

Pinion thrust washer |

CDF |

THRUSTWASHER - BEARING |

| 009 |

42449 |

Pinion seal |

CD |

SEAL - PINION |

| 010 |

34592 |

Pinion Yoke slinger |

CD |

SLINGER - END YOKE |

| 012 |

30275 |

Pinion nut washer |

CDF |

WASHER - PINION NUT |

| 013 |

30271 |

Pinion nut |

CDF |

NUT - PINION |

| 017 |

34822 |

Diff cover bolt |

CDF |

BOLT - CARRIER COVER (QTY 10 |

| 018 |

34687 |

Diff cover gasket |

CD |

GASKET - CARRIER COVER |

| 020 |

48632-1 |

Diff main bearing cap bolt |

CDF |

BOLT - DIFFERENTIAL BEARING CA |

| 021 |

706047x |

Carrier bearings |

CDF |

DIFFERENTIAL BEARING KIT |

| 022 |

708012 |

Carrier shims |

D only C & F # 706378X |

KIT - DIFF BRG ADJ SHIM (INC 1 |

| 024 |

30266 |

Ring gear bolt |

CD |

BOLT - DRIVE GEAR (QTY 12) |

| 026 |

34367 |

Spider gear |

CDF |

PINION |

| 027 |

34729 |

Side gear thrust washer |

CDF |

THRUST WASHER |

| 028 |

34730 |

Spider gear thrust washer |

CDF |

THRUST WASHER |

| 029 |

44810 |

Roll pin – cross pin |

CDF |

LOCK - DIFFERENTIAL SHAFT |

| 030 |

30263 |

Carrier Cross pin |

CDF |

DIFF SHAFT |

| 031 |

36487 |

Inner axle seal |

CD |

SEAL & GUIDE TUBE |

| 706395x |

King pin rebuild kit |

CD |

KIT - KING PIN PARTS |

|

| 032 |

620058 |

Upper kingpin seal |

CD |

SEAL - KING PIN - UPPER |

| 033 |

37305 |

Lower kingpin seal |

CDF |

RETAINER - GREASE |

| 034 |

41777 |

Lower kingpin bearing oil seal |

CDF |

SEAL - OIL |

| 035 |

706150x |

Lower kingpin bearing and race |

CDF |

KIT - BEARING - KING PIN - L |

| 041 |

30875 |

Upper kingpin cap bolt |

CDF |

NUT - HEX TAPERED |

| 044 |

37307 |

Upper kingpin cap gasket |

CDF |

GASKET - KING PIN CAP |

| 044 |

620132 |

Upper kingpin cap |

CDF |

CAP - KING PIN - UPPER (RH ONL |

| 045 |

37300 |

Kingpin spring |

CDF |

SPRING - PRESSURE |

| 046 |

620180 |

Kingpin spring retainer |

CDF |

GEAR |

| 047 |

41886 |

Upper kingpin bushing |

CDF |

BUSHING - KING PIN |

| 048 |

37302 |

Kingpin |

CDF |

PIN - KING |

| 051 |

37879 |

Spindle stud |

CD |

BOLT - HEX |

| 052 |

37299 |

Lower kingpin cap |

CDF |

CAP - KING PIN BEARING LOWER |

| 053 |

500357-13 |

Lower kingpin cap lockwasher |

CDF |

LOCKWASHER (KING PIN CAP - LOW |

| 054 |

500412-13 |

Lower kingpin cap bolt |

CDF |

BOLT - HEX (KING PIN CAP - LOW |

| 056 |

37308 |

Stub shaft slinger |

CD |

SLINGER |

| 056 |

700014 |

Spindle bearing and seal kit |

CD |

KIT - SPINDLE |

| 057 |

620062 |

Inner spindle seal |

CD |

SEAL - NEEDLE BEARING |

| 058 |

37312 |

Spindle thrust washer / spacer |

CD |

SPACER - WHEEL BEARING SPINDLE |

| 059 |

37311 |

Outer spindle seal |

CD |

SEAL - OIL |

| 060 |

620063 |

Spindle bearing |

CDF |

NEEDLE BEARING - SPINDLE |

| 062 |

36880 |

Spindle nut |

CD |

NUT - BRAKE MOUNTING |

| 063 |

48816 |

Hub seal (inner wheel bearing seal) |

CD |

SEAL - GREASE |

| 064 |

706411x |

Inner wheel bearing and race |

CDF |

INNER WHEEL BEARING |

| 065 |

706074x |

Outer wheel bearing and race |

CDF |

INNER WHEEL BEARING KIT |

| 075 |

707083X |

30 spline drive flange kit |

CF |

KIT – DIFF PLATE AND DISC (T/L) |

Front Dana 60 Pinion Yoke options:

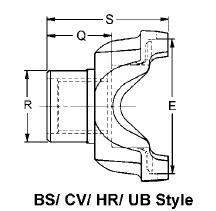

Refer to following diagrams when reading chart.

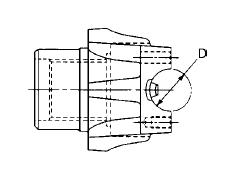

NOTE: D is the Ujoint cap diameter

E is the outside dimension across the joint from cap to cap

R is the diameter of the machined seal surface

Q is the length though the hole, and while not absolutely critical should be close o as to allow proper pinion nut tightening

S is the total "length" of the yoke, and as such, assuming Q is close, will affect driveshaft length slightly

Bold text in the table indicates factory application, according to Drive Train Specialists. Note the differences in max allowable joint angles - may be important / helpful in some applications.

| Ujoint

series |

Joint

width E |

Cap

dia. D |

U-bolt kit | Strap kit | Major

Diameter |

Ground Hub diameter (R) | Length through hole (Q) | Centerline to end (S) | Joint Angle | Bearing Strap (BS) or U-bolt (UB) | Yoke plus slinger part # | Slinger part # | Yoke Part # |

| 1310 | 3.219 | 1.062 | 2-94-28X | 1.2760 | 1.8750 | 1.5000 | 2.5310 | 18.0 | UB | 2-4-3781X | 30798 | 2-4-3771 | |

| 2-70-18X | 1.2760 | 1.8750 | 1.5000 | 2.9380 | 18.0 | BS | 2-4-3801-1X | 34592 | 2-4-3791-1 | ||||

| 2-94-28X | 1.2760 | 1.8750 | 1.5000 | 2.9380 | 18.0 | UB | 2-4-3801X | 34592 | 2-4-3791 | ||||

| 2-70-18X | 1.2760 | 1.8750 | 1.5000 | 2.9380 | 22.0 | BS | 2-4-6551-1X | 34592 | 2-4-6541-1 | ||||

| 2-70-18X | 1.2760 | 1.8750 | 1.5000 | 2.9964 | BS | 2-4-8391-1X | 34592 | 2-4-8331-1 | |||||

| 1330 | 3.625 | 1.062 | 2-94-28X | 1.2760 | 1.8750 | 1.5000 | 2.9380 | 20.0 | UB | 2-4-3671X | 230421 | 2-4-3661 | |

| 2-94-28X | 1.2760 | 1.8750 | 1.5000 | 2.9690 | UB | 2-4-4291X | 34592 | 2-4-4031 | |||||

| 2-70-18X | 1.2760 | 1.8750 | 1.7000 | 3.1880 | BS | 2-4-8421-1 | |||||||

| 1330-F | 3.625 | 1.125 | 2-94-58X | 1.2760 | 1.8750 | 1.5000 | 2.9380 | 18.5 | UB | 2-4-8051X | 41195 | 2-4-8041 | |

| 2-94-58X | 1.2760 | 1.8750 | 1.5000 | 2.9380 | 20.0 | UB | 2-4-5311X | 34592 | 2-4-5301 | ||||

| 1350 | 3.625 | 1.188 | 3-70-28X | 1.2760 | 1.8750 | 1.5000 | 3.0000 | 22.5 | BS | 3-4-12211-1 | |||

| 1.2760 | 1.8750 | 1.5000 | 3.0000 | 22.5 | BS | 3-4-5731-1X | 34592 | 3-4-5721-1 | |||||

| 1.2760 | 1.8750 | 1.5000 | 3.0000 | 22.5 | BS | 3-4-13031-1X | 45799 | 3-4-12771-1 | |||||

| 1.2760 | 1.8750 | 1.5000 | 3.0000 | 22.5 | BS | 3-4-13031-2X | 45799 | 3-4-12771-2 | |||||

| 1410 | 4.188 | 1.188 | 3-70-28X | 1.2760 | 1.8740 | 1.4200 | 3.1850 | 22.5 | BS | 3-4-11891-1X | 34592 | 3-4-11851-1 | |

| 3-70-28X | 1.2760 | 1.8750 | 1.5000 | 3.1880 | 22.5 | BS | 3-4-5711-1X | 34592 | 3-4-5701-1 | ||||

| 3-94-18X, | 1.2760 | 1.8750 | 1.5000 | 3.1880 | 30.0 | UB | 3-4-8731 | ||||||

| 1480 | 4.188 | 1.375 | 3-70-38X | 1.2760 | 1.8750 | 1.5000 | 3.5000 | 22.5 | BS | 3-4-13391-1X | 34592 | 3-4-9531-1 | |

| 7290 | 1.125 | 1.2760 | 1.8750 | 1.5000 | 3.3590 | 30.0 | BS | 2-4-7681-1X | 34592 | 2-4-7671-1 |

| |

|

Assembly Specifications:

| Item | Spec | Unit |

| Pinion bearing preload (new) | 20-30 | inch pounds |

| Pinion bearing preload (used) | 8-10 | inch pounds |

| Pinion bearing HP60 used in rear | 12-20 | inch pounds |

| Backlash | 6-10 | thousandths of an inch |

| front wheel bearing freeplay | 1-10 | thousandths of an inch |

| Ring gear bolt torque | 110 | foot lbs |

| Bearing cap bolt torque | 80 | foot lbs |

| Cover bolt torque | 30-40 | foot lbs |

| Pinion nut torque | 240-300 | foot lbs |

| Cover fill plug | 40 | foot lbs |

| Yoke U-joint bolts | 8-15 | foot lbs |

| wheel brg adjusting nut | 50 | foot lbs - then back off approx. 90* |

| wheel brg locknut | 50-70 | foot lbs |

| Kingpin | 500-600 | foot lbs |

| Upper and lower kingpin cover bolts | 70-90 | foot lbs |

| Spindle nuts (the ones that hold the spindle to the knuckle.) | 65 | foot lbs |

Dana 60 Gear ratio availability:

| Ratio | Cut | Teeth (ring - pinion) |

| 3.54 | regular / reverse | 46-13 |

| 3.73 | regular | 41-11 |

| 4.10 | regular / reverse | 41-10 |

| 4.30 | regular (uses 4.10 carrier) | |

| 4.30 | reverse | |

| 4.56 | regular / reverse / reverse thick | 41-9 |

| 4.88 | regular / reverse / reverse thick | 39-8 |

| 5.13 | regular / reverse / reverse thick | 41-8 |

| 5.38 | regular / reverse | |

| 5.86 | regular | 41-7 |

| 6.17 | regular | 37-6 |

| 7.17 | regular | 43-6 |

Anything over 5.38 Dana says are for industrial applications only, meaning they are cut for strength, not being quiet.

As far as I know, nobody makes thick gears for the standard cut D60 front.

Dana 60 limited-slip availability:Dana Trac-lok 4.10 & down pn 707090-4X / 4.56 & up pn 707097-4X

Dana Power-lok

Dana 60 locker availability:ARB 4.10 & down pn RD36 / 4.56 & up pn RD35

Detroit Locker 4.10 & down pn 225SL29B / 4.56 & up pn 225SL29A

Powertrax Lockright pn 2620

Powertrax No-Slip pn 92-0460-3500 (for open carrier) pn 92-0460-3520 (for Trac-lok carrier)

Full Spool (35 spline only)

Front D60 Stock Spicer Axleshafts:Older stock Dana 60 35 spline inner axles (particularly pre-1980) neck down from 1.5” at the splines to 1.3" in the middle of the shaft.

Later Spicer inner axles (1980+) are 1.500” at the splines. 1.562" at the seal surface, and taper up to 1.625” at the largest diameter. The part numbers are the same for the whole run ('77-'91), but around '80, they changed to the bigger shafts. (They were gradually phased in over a few years)

In order to upgrade an older "neck down" shaft to the larger models, one need only order the standard stock part number or application, and, assuming your supplier doesn't have any really old stock, you should get the larger shafts. This is true for all 3 - Chevy, Dodge, and Ford.

| This

picture illustrates the older “neck-down shaft” on top, and the later “big”

axle below. These particular shafts are Dodge Dana 60 shafts.

Photo courtesy Wolf359 |

|

1978 and later Stock Dana 60 outer 30 spline stub shafts (pn 40955) are 1.3125" at the splines (major diameter) and approximately 1.250" at the shank.

For comparison, A Dana 44 19 spline stub measure 1.155" at the splines and 1.060" at the shank

Spicer 35 Spline stub shafts pn 3-82-871 (originally for D70, but work in GM/Dodge D60 without modification) are 1.5” at the splines and 1.375" at the shank. In order to run the 35 spline stub shafts in an axle that has Chevy/Dodge knuckles-out with "internal" style hubs, all you have to do is swap in the stub shafts and a 35 spline lockout or drive flange (sources for these listed later in article). To use them in a Dodge D60 with external hubs, the only trick is sourcing or fabbing a 35 spline external lockout or drive flange (more on these later too). They can work in a Ford d60 too - more on this later

The 3-82-871 stub axle is used in Dana 70BF front axles assemblies. These axles are the open knuckle style Dana 70 front. The axles are used in very heavy duty light trucks (under 2 1/2ton) such as Ford f550 forestry trucks or rescue and firetrucks. The Dana 70 BF front axle is an "off-highway equipment" axle also used in forklifts, pavers, tow motors, etc. According to the Spicer catalog/index it was never produced with lockouts. Only the old style closed knuckle 70's had lockouts and they used an external style hub. Warn makes 35 spline lockouts for the internal style hub...and the external style 35 spline lockout has long been discontinued.

This pic illustrates a Dana 44 19 spline stub shaft (bottom) vs. a Dana 60 30 spline stub shaft (top)Photo courtesy D60 |

|

||

| Dana 60 30 spline stub (right) vs. the Dana 60 35 spline stub (left). |  |

||

|

Dana 60 30 spline stub (left) vs. the Dana 60 35 spline stub (right).

Photo courtesy Wolf359 |

|

||

| Dana 60 30 spline stub (left) vs. the Dana 60 35 spline stub (right). |  |

||

| Spicer 35 Spline stub shafts pn 3-82-871 |  |

||

| Stock 30 spline stub shaft in D60 hub | 35 spline stub shaft in D60 hub | Stock 30 spline stub shaft in D60 spindle | 35 spline stub shaft in D60 spindle |

Photo courtesy Shawn Spickler, Off-road.com |

Photo courtesy Shawn Spickler, Off-road.com |

Photo courtesy Wolf359 |

Photo courtesy Wolf359 |

Stock Dana Spicer Axleshaft specs:

Click HERE for the new table giving the axleshaft specs for all Front Dana 60, Dana 61, and Dana 70 axles. Includes length of both inner and outer (stub) shafts as well as U-joint size / series.

Also available in .XLS format

Moser Engineering

make an alloy 35 spline D60 front axle inner or outer, in the Ford or Chevy

configuration.

It's made out of the same material as their race axles (1541M, induction hardened)

and does not have any taper the full length. They want $395 for the outers a

pair and the same for the inners a pair. They are making them with the option

of 30 or 35 spline outers. They are $395 a pair

for the inners and the same $395 for a pair of outers. They come with no warranty.

Here's what Moser says about their new axles:

"These virtually indestructible front axles are much stronger than stock, due in part by the induction hardened alloy steel and also the fact the axles are beefed-up considerably around the u-joint. Designed for use with Spicer #5-332X u-joints, the Moser 60 Front Axles are available in both inner and outer shafts. Inner shafts are available in 35 spline, while the outer shafts are available in both 30 and 35 spline. The newest Moser Engineering indestructible axles ship in just two-days from the order date. $395 per pair "

Dutchman also sell Spicer Front Axle Shafts:These are not aftermarket alloy or chrome-moly axles, but stock Spicer alloy. They are supposed to be developing an aftermarket alloy shaft, but it is not yet available.

From their web site:

| Single |

Pair |

|

| New Spicer inner shafts: Dana 60, up to 32" long (5-332x, 1 3/8" U-Joint cap diameter only) |

$160 |

$295 |

| New Spicer Outer shafts: Dana 60 (Chevy & Ford 30 & 35 spline) |

$76 |

$140 |

How strong are the different axle shafts?

(note these figures are subject to much debate)

Standard Dana axles (1040 steel, induction hardened)

30 sp 1.31" 6,044.1 ft/lbs

35 sp 1.50" 8,966.2 ft/lbs.

Moser

Engineering (1541m, induction hardened)

30 Spline - 6,200 ft/ lbs.

35 spline - 9,600 ft/lbs.

Aftermarket 4340 steel, thru hardened

30sp 1.31" 9,923.5 ft/lbs

35 sp 1.5" 14,721 ft/lbs

The

Formula is:

Yield Torque (in/lb)= Tensile Strength ( psi) x polar moment of inertia/ radius

of material

The theoretical axle size by spline to percent strength increase, assuming same material, diameter, and heat treat is: 30 spline – 35 spline: ~40%

Front Dana 60 axle U-joints:Original hot forged joint: Spicer 5-332X - solid cross, non-greasable

New Cold Forged joint (Spicer calls these the “Spicer Life Series” )

Greasable: Spicer SPL55-4x also called 5-733x

Permanently Sealed: SPL55-3x, also called 5-806-x

5-88x u-joint is that listed for some stock Dana70 applications. It is the same size as a 1480 series (5-332x), but uses external snap-rings for retention (like a driveshaft ujoint).

Note, according to the Dana/Spicer website (http://www2.dana.com/expert/ )

5-332x is obsolete – superceded by SPL55-3x

5-88x is active

SPL55-4x is active

SPL55-3x is active

5-733x is obsolete, superceded by SPL55-4x

5-806-x is active

| There have been many widely varied reports on the internet about this, with a lot of figures around 20% being published. However, I have been unable to get any confirmation of this, or seen any published numbers in any literature from Dana Spicer. However, if we examine a pic comparing the old and the new, it seems reasonable to assume at least some marginal increase in strength, if only due to the cold forging process and smaller grease hole diameter. Oftem when a front Dana 60 ujoint breaks, it does so at the base of the trunion where the hole bottom is located. It's quite likely that the smaller hole and supposedly stronger manufacturing process will net some increase in strength in the shaft of the trunion. |  |

The other option, and likely last word in ultimate D60 ujoint strength are the new 4130 forged ujoints from CTM racing.

| Part number

is the CTM ujoint for a front Dana 60 axle. Be aware that these u-joints

are designed to use "full-circle" snap rings and so will require

a little machining of the ears of the yokes of stock shafts to allow the

snap-rings to fit, or the use of custom D60 front shafts designed for full

circle snap rings. These ujoints are also much stronger than stock Spicer shaft yokes |

|

Front Dana 60 locking hub and drive flanges:

Assuming correct match with splines on stub shaft, all will interchange between Ford, Chevy, and Dodge Internal style hubs.

| Type | Inner Splines | Style | Manufacturer | Part number | Notes |

| Drive Flange | 35 | Internal | Warn | 39346 | full float drive flange kit (pair) |

| 35 | Internal | Spicer | 620861 | single drive slug, not the dust cover, spacer, snap ring, or spring ## | |

| 35 | Internal | Poly Performance | Picture 1 | 4340 induction hardened and the caps will be anodized black with a little logo on them....They will go for about 175 bucks for the pair. | |

| 35 | External | Spicer | 26049x | Unfortunately Long discontinued ^^ | |

| 30 | Internal | Warn | 39340 | ||

| 30 | Internal | Spicer | 37994 | ||

| 30 | External | Spicer | |||

| Locking Hub | 35 | Internal | Warn | Single hub 62672 | New, made for front axle |

| 35 | Internal | Warn | Single

hub Pair of hubs 38787 38786 |

The Warn hubs are actually made for the 9" or D60 full float rear kit. warn calls them "Heavy Duty Rear Full Floater Hublock" ** | |

| 35 | Internal | Spicer | |||

| 30 | Internal | Warn | Standard

Premium 11690 38826 |

||

| 30 | Internal | Spicer | discontinued, 81 was the last year for them oem | ||

| 30 | Internal | Superwinch | 400439 | Single hub | |

| 30 | Internal | Milemarker | 449 SS |

Single hub | |

| 30 | External | Warn | Single

hub Pair of hubs 38428 38370 |

Unconfirmed, listed as "Flange Mount Hublock 30 spline" | |

| 30 | External | Superwinch | Single hub 400541 | Unconfirmed, listed as D70 lockout | |

| 30 | External | Milemarker Selectro | Single hub 11034-01 |

** These do have lock screw

on the dial and a positive blocker ring. The blocker ring and set screw are

mods specifically for the intended rear axle application. Most rear axles are

bent and this creates a circular motion on the end of the shaft as the axle

spins and this circular motion tends to unlock locking hubs by pushing the gear

out against the spring pressure. On a front end, any misalignment is taken up

by the spindle bearing fit and the locking hub clearances, plus its got a ujoint

between the tube and spindle so the spring pressure on the gear is enough to

keep it engaged. The blocker ring makes a solid stop for the rear hub gear to

hit against and keep it from coming unlocked. For a front axle, the blocker

ring is not necessary, and neither is the set screw. The blocker ring makes

it difficult to lock the hubs because you have to rock or move the vehicle so

the splines line up. Since this is such a pain, we removed the blocker ring

so the hubs work just like normal hubs. The set screw is in there for the same

reason, just to keep the dial from rotating and unlocking. Instead of having

a "click" when you turn them to lock or free, there's nothing. The

allen wrench and set screw is used to keep the hubs in the selected position.

The set screw is also a pain but some guys like the screw since it makes it

harder for someone to mess with the hubs. You can modify the set-screw as follows:

Buy the following from a hardware store:

1 short set-screw (about 3/16 inch)

1 spring (smaller in diameter than the set-screw)

1 BB (or small ball bearing)

Replace the Warn set screw with the BB/spring/set-screw combination. You'll

have to trim the spring short enough that it allows the BB to slide out of the

detent within the hub.

## Related Spicer part numbers:

37996 dust cover for drive flange (discontinued)

37997

spacer for drive flange

^^ Sources for external style 35 spline drive flanges include Dynatrac, WMS, a fellow on the POR BB by the name of Donovan, or custom made (often from some 35 spline side gears that are annealed and then welded to a drive plate that has the 8 bolt external bolt pattern drilled in it)

Notes:

- Many folks have reported good success having 30 spline hubs and drive flanges broached for 35 splines.

- Ford oem 30 spline locking hubs are 5 pieces vs. Warn's two pieces (not including snap rings.)

- Teralow D60 locking hubs are made by Milemarker.

- You can use the dust cover (cap), spacer, snap ring, spring, etc. from a 30 spline drive flange with the 35 spline drive flange.

- Warn 35 spline Premium locking hubs have been bench-tested to failure at 967 ft/lbs

| 35 spline

internal style drive flange Photo courtesy Wolf359 |

|

| Warn 35

spline locking hubs specifically for 35 spline D60 front axles. PN 62672

Photo courtesy Shaker |

|

| Warn Heavy

Duty Rear Full Floater Hublock PN 38787 Photo courtesy Shawn Spickler, Off-road.com |

|

| Warn Heavy

Duty Rear Full Floater Hublock PN 38787, showing "blocker ring"

mentioned above. Photo courtesy Shawn Spickler, Off-road.com |

|

New 35 Spline drive gears available from www.polyperformance.com Drive gears are made from 4140 and then heat treated. C.N.C. machined using the latest HAAS equipment. Black oxide with wax coating finish for corrosion resistance. Replaces existing

35 spline locking hub or drive gear assembly |

|

| Here are some

nice pics coutesy of 3/4tonYJ of some stock 30 spline Dodge externa; drive

flanges he had broached to 35 spline and polished.

He paid $85 for the pair, and the work was done by: Knoll Racing 323-255-3639 |

|

Front D60 part numbers:

Dana

60 Front Spindle Nut Socket Napa #775-9025 (I don't know if this is 4 or 6 prong)

GM D60 spring plates Part numbers 370055

and 370056

Pep Boys Motormite U-bolt part # 35661 - measures 5/8" x 8 1/4" x 3 1/8" fit perfectly a leaf spring pack that measures 2 1/2" and there is another 1/2" left on the bolts.

Chevy D60 SRW wheel hub 15635530 - $297 from http://www.gmpartsdirect.com

Chevy/Dodge D60 SRW wheel hub SS7009 - $184 from http://www.sixstates.com

* Note: Apparently Six States bought the hub molds from GM & are reproducing them at a local foundry.

Spindle-nut part numbers and sources:

Reider racing For one complete front axle you need four 33732(lock-nut), two 33733 (lock washer), two 33734 (flat washer). These are Dana patr numbers. All 8 pieces for about $22.00 |

|

Parts Mike Washer (Pin

style lock) #PM 33733 $1.95 |

|

| Dorman spindle lock nut kit #05303 for an 85 K30 are about $23 each |

Note: There are 4 and 6 slot locking nuts available - and they appear to use the same part numbers. Not also the different lock-washer methods, one has the holes that index onto a pin on the lock nut (4 slot nut style - lower pic). The other has the "bend over" tabs - although they both appear to share the same Dana part number.

Snap Rings for use with 35 spline stub shafts: Industry #143 or a Dynaline #22950, 1.438" diamater, outer snaps.

Front D60 Kingpin rebuild:| Diag. # |

Dana Spicer part number | Description | Interchanges between |

|

| 32, 33, 34, & 35 |

706395x |

King pin rebuild kit |

CD |

|

| 032 |

620058 ** |

Upper kingpin seal |

CD |

|

| 033 |

37305 |

Lower kingpin seal |

CDF |

|

| 034 |

41777 |

Lower kingpin bearing oil seal |

CDF |

|

| 035 |

706150x |

Lower kingpin bearing and race |

CDF |

|

| 041 |

30875 |

Upper kingpin cap bolt |

CDF |

|

| 043 | GM part no. 0047-1750 | Upper kingpin cover | C | |

| 044 |

37307 |

Upper kingpin cap gasket |

CDF |

|

| 044 |

620132 |

Upper kingpin cap |

CDF |

|

| 045 |

37300 |

Kingpin spring |

CDF |

|

| 046 |

620180 |

Kingpin spring retainer |

CDF |

|

| 047 |

41886 |

Upper kingpin bushing |

CDF |

|

| 048 |

37302 |

Kingpin |

CDF |

|

| 051 |

37879 |

Spindle stud |

CD |

|

| 052 |

37299 |

Lower kingpin cap |

CDF |

|

| 053 |

500357-13 |

Lower kingpin cap lockwasher |

CDF |

|

| 054 |

500412-13 |

Lower kingpin cap bolt |

CDF |

** only sold in quantity 10

| 047 - Upper

kingpin bushing pn 41886 048 - Kingpin pn 37302 Photo courtesy Shaker |

|

| 045 - Kingpin

spring pn 37300 046 - Kingpin spring retainer pn 620180 Photo courtesy Shaker |

|

| 32, 33,

34, & 35 - King pin rebuild kit pn 706395x Photo courtesy Shaker |

|

| Kingpin

rebuild kit from Parts Mike

Photo courtesy PartsMike |

|

Front D60 bearings and seals:

Referring to the following diagram, D60 front axle spindle / wheel bearings and seals are:

| Diagram # | Description | Dana Spicer # | Timken # | National # | GM # | Ford # | Chrysler # |

| 57 | Inner Spindle seal | 620062 | 710044 | 14012967 | D8TZ1175C | 3894121 | |

| 59 | Outer spindle seal | 37311 | 710045 | 462811 | D8TZ1175A | ||

| 60 | Spindle needle bearing | 620063 | B2414 | 1400967 | D8TZ3123A | 4089296 | |

| 57, 58, 59, and 60 | Spindle seal and bearing kit | 700014 | SBK3 | 14009626 | 4086641 | ||

| 63 | Wheel Bearing hub seal | 48816 | 240435 | 340435 | 2090539 | ||

| 64 - left | Inner wheel bearing cone (bearing) | 565906 | 387-AS | 387AS | 9436882 | C5NNA767A | |

| 64 - right | Inner wheel bearing cup (race) | 550583 | 382-A | 382A | 142223 | C5NNA768A | 568500 |

| 65 - right | Outer wheel bearing cone (bearing) | 565918 | LM104911 | 4TLM104911A | 7451813 | C7TA1239A | 2953549 |

| 65 - left | Outer wheel bearing cup (race) | 565905 | LM104949 | 4TLM104949 | 2852729 | C7TA1240A | 2825729 |

| 65 | Outer wheel bearing cup and cone set (bearing and race) | SET38 | BWLM104949LM1 | 7451812 | E5TW1239AA | ||

| 67 | outer spindle collar (outer spindle locknut) | 621027 | |||||

| 68 | inner spindle collar (inner spindle locknut) | 660568 | |||||

| 69 | spindle nut lockwasher | 621028 | |||||

| not shown | inner axle seal | 62510 | 475960 | 15527650 | D8TZ1175B | T2560 |

**

For a larger interchange chart, showing (where applicable)

Victor, Sealed Power, Federal Mogul, Chicago Rawhide, SKF, and many more numbers

click HERE: **

The following pics show some of the parts in greater detail, with the numbers from the exploded diagram in blue. Pics courtesy of Shaker.

| Spindle bearing and seal kit. | D60 spindle locknuts and washer | D60 inner axle seal |

|

|

|

Earlier version uses a lockring with tabs that bend over the spindle nuts. The later version has a nipple on the inner spindle nut that fits into a lockring and another spindle nut to secure it (pictured).

Converting DRW hubs to SRW hubs:NOTE: This section is included because so many people ask about it. It became a popular procedure in the past, since GM was the only source for SRW hubs, at a cost of something like $1100US A pair. However, now new hubs are available through SixStates for only about $165US each. For that price, that is certainly the best way to convert DRW to SRW axle. The problem with the "homebrew" machined version illustrated below, is that the small inner tabs on the DRW rotor were never designed to carry the entire weight of the vehicle - only to handle the rotational force on the brake rotor. I would certainly not recommend this procedure for use on a vehicle that will ever see street duty.

The SRW and DRW front axles are identical EXCEPT for the wheel hub and rotor - same spindle, bearings, and lockout. The DRW wheel hub has a wheel mounting flange mounted on it about 4-5" from where the SRW wheel would mount. This makes the DRW axle 4-5" wider on each side. This was done to more closely match the width of the DRW rear axle, and to allow the DRW trucks to carry a single spare tire mounted on the largely dished "budd" style DRW wheel. Also, the rotor is bolted to the DRW hub with 8 9/16-NC bolts inboard of the wheel mounting flange, in the same position as the SRW hub, allowing the use of the same brakes on either (as opposed to the SRW hub which uses the wheel studs to pin the rotor and hub together). Because of this, the holes in the DRW rotor are smaller than in the SRW rotor, since the DRW rotor holes need only to clear the 9/16 bolts, as opposed to the SRW rotor holes which are larger to fit the knurled shoulder of the SRW wheel studs - other than that, the rotors are identical and DRW rotors can be used with SRW hubs if the 8 holes are drilled larger. The last difference is that between the DRW mounting surface and where the SRW mounting surface would be, the DRW hub 'bulges' - enough so that it will not fit through the center hole in the stock SRW wheel. Aftermarket wheels may not be an issue if they have larger center holes.

To convert from DRW to SRW you can either swap on a complete SRW front hub/rotor assembly, it is a direct swap or swap on a SRW hub and drill out the holes in the DRW rotor so it can be re-used.

Alternatively you can convert your front DRW hubs to SRW hubs as follows:

A note on studs:

Basically

when they list studs, they list the thread and pitch of the studs (i.e.: 9/16-18

or whatever), the length of the stud (which is the length of

the part the lug nuts thread on to), and diameter of the 'knurl', which is the

splined part of the stud, and often the length of the knurl (called the

shoulder length).

Dorman part # 610 - 283 is the part number for the STANDARD 1 ton Chevy, it

fits 77-91 Chevy trucks. 9/16-18 thread, 2 17/32

long, .650 shoulder, 15/16 shoulder length.

Dorman part # 610 - 303 - fits 77-91 Chevy trucks. 9/16-18 thread, 3 inches

long, .678 shoulder, 15/16 shoulder length. It is

identical in most measurements (including thread) to the 610-283, except that

it is somewhat longer and has a knurl of .678. In actuality, the ones I measured

never mic'd to more than .672.

My friend Chad who did a DRW-SRW conversion reports:

"If

you find that even Dorman 303 is too small, Bicknell Racing Products sells a

wheel stud, part number BRP2059, which is 5/8 Course thread, 2.75

inches long, .685 shoulder with a .800 shoulder length. This stud was meant

to be used in a hole drilled out to 43/64, which is the exact size of the

hole I used, so this is the stud I ended up using, and I can report that it

fits quite nicely into a 43/64 hole. They also sell another wheel stud,

BRP2075, which is exactly the same, but 3.75 inches long. The shorter stud worked

fine in my application, but some people may want more stud sticking

out. BRP2051 is the lug nut that matches, but I think any 5/8 course lug nut

would work fine."

The important thing here is to select the studs you need to use FIRST, measure

the knurl diameter carefully (mic it) and then have the holes drilled slightly

undersize for a proper tight interference fit. Standard class V interference

fit (tight - semi-perm. assembly) the interference (shaft bigger than hole)

should be between 3 and 18 thou. Given this, and the fact that the measurement

of the knurl will be the major diameter of the splines, I would shoot for a

15 thou undersize hole. Given the measured knurl size of .672, this would

mean a hole diameter of .657. A 21/32 drill bit is .656250, yielding an

interference fit of 15.7 thou. That should be just about perfect, but MEASURE

TWICE, drill once!

** CLICK HERE TO GO TO PAGE 2 OF THE 60 AXLE TECH ARTICLE**

[Page 1] [Page2]